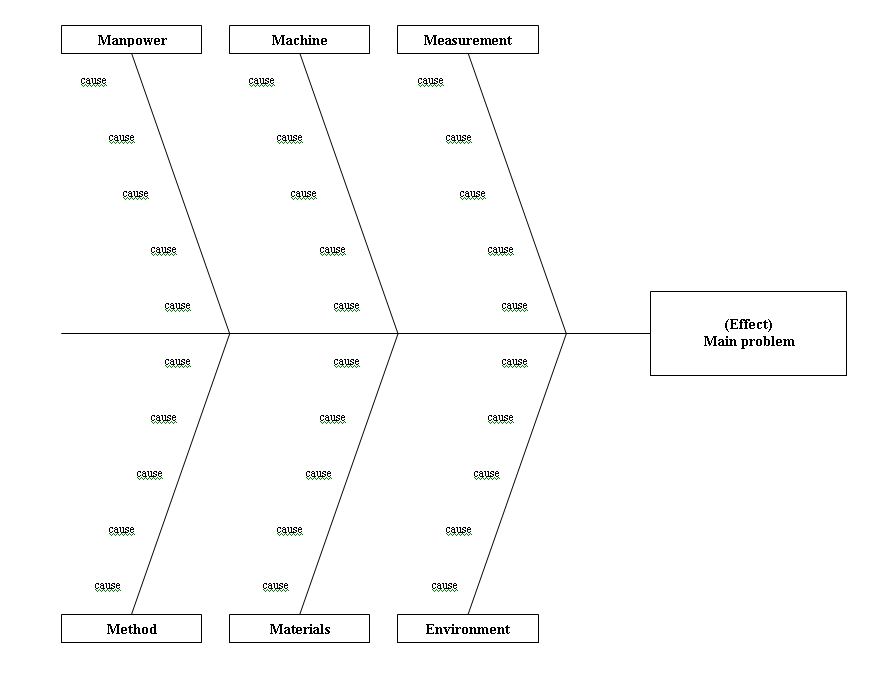

Subtitle for the diagram (recommended the Six Sigma project name)Ī vector of colors for a personalized drawing. Ss.ceDiag ( effect, , causes, main = "Six Sigma Cause-and-effect Diagram", sub, ss.col = c ( "#666666", "#BBBBBB", "#CCCCCC", "#DDDDDD", "#EEEEEE" ) )Ī short character string that represents the effect we want to analyse.Ī vector of characters that represents the causes groups.Ī vector with lists that represents the individual causes for each

#Ishikawa diagram in six sigma pdf#

ss.heli: Creates a pdf file with the design of the Paper Helicopter.ss.data.wbx: Woodboard location for profiles.ss.data.thickness2: Metal Plates thickness (extended).ss.data.thickness: Metal Plates Thickness.ss.data.strings: Data set for the Guitar Strings example.ss.data.pc.r: Data set for the printer cartridge example, by region.ss.data.pc.big: Larger data set for the printer cartridges example.ss.data.pc: Data set for the printer cartridge example.ss.data.pb4: Data for Practicle Boards Example - number of defects.ss.data.pb3: Particle Boards Example - Attribute data.ss.data.pb2: Particle Boards Example - by Groups.ss.data.pb1: Particle Boards Example - Individual Data.

ss.data.doe2: Data for the pizza dough example (robust design).ss.data.ca: Data for a filling process in a winery.ss.data.bolts: Data for the bolts example.

ss.data.bills: Errors in bills data set.ss.data.batteries: Data for the batteries example.ss.ci: Confidence Interval for the mean.ss.cc.constants: Functions to find out constants of the relative range.ss.ca.yield: Main calculations regarding The Voice of the Process in.smoothProfiles: Regularise set of profiles.SixSigma: Six Sigma Tools for Quality and Process Improvement.plotControlProfiles: Profiles control plot.outProfiles: Get out-of-control profiles.Handbook of Lean Manufacturing in the Food Industry. ^ "6M's in Six Sigma (Six Ms or 5Ms and one P or 5M1P)".Reliability engineering : a life cycle approach. Failure mode and effects analysis (FMEAs) for small business owners and non-engineers : determining and preventing what can go wrong. ^ "Fishbone diagram: Solving problems properly".^ "How to use the fishbone diagram to determine data quality root causes".Improving complex systems today : proceedings of the 18th ISPE International Conference on Concurrent Engineering. Milwaukee, Wisconsin: American Society for Quality. Mind bias: the fact that individual behaviour and choices may be driven by cultural, historical and own experience context. Moreover in addition to 9M model items you may consider also:ġ0. Misinterpretation of reality: science represents reality by means of models but complete knowledge of reality is not attained. Matter-of-fact technology limitations: no way to reduce to zero failure riskĩ. Mandatory matters: such as the rules which originate from laws, standards, Body regulations or organization policies/ways of conductĨ. In addition to following identified sources that can affect the desired outcome of a process or preclude opportunities:ħ. Mission / mother nature (purpose, environment).These have been expanded by some to include an additional three, and are referred to as the 8 Ms:

0 kommentar(er)

0 kommentar(er)